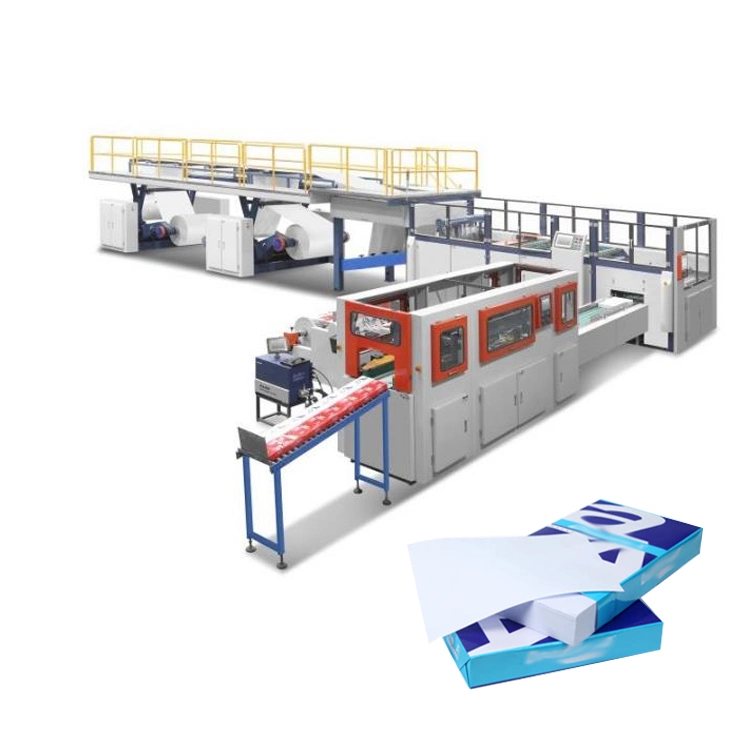

Factory Price Automatic A4 Copy Paper Cutting and Packaging Machine Paper Cutting Machine

Basic Info

| Model NO. | 1100 |

| Automation | Automatic |

| Certification | CE |

| Customized | Customized |

| Condition | New |

| After-sales Service | 1year |

| Max Unwinding Diameter | 1400mm |

| Min.Cutting Length | 20mm |

| Machine Speed | 10-200times/Min |

| Raw Material | Waste Paper, Wood Pulp etc. |

| Cutting Precision | ±0.2mm |

| Power | 16kw |

| Transport Package | Seaworthy |

| Specification | 8800× 2000× 2000mm |

| Trademark | YDF |

| Origin | Shandong Province China |

| Production Capacity | 5tpd |

Packaging & Delivery

Package size per unit product 3000.00cm * 30000.00cm * 5000.00cm Gross weight per unit product 80000.000kgProduct Description

Machine Introduction

BUYING GUIDE

Under the purpose to give our clients best suggestions and recommend more suitable machine model. Please check the following information of a4 paper cutting machine and feedback us your idea, we can make accurate and best quotation completely according to your real requirement1.What is the width of your feeding paper roll? 640mm? 850mm? 1060mm? 1270mm?

2.How many feeding rolls you want in the cutting machine? Our machine can equip with 1 roll, 2 rolls, 4 rolls. it is up to your real production capacity.

3.Could you please let us know how many reams you want for per minute?

1-2 reams/min? 4-6reams? 10-12reams/min? 18-22reams/min?

4.Could you tell us which kind packaging material you will need?

In paper material or in plastic packaging material?

| Max unwinding diameter | φ1100mm |

| Max cut width | 1100mm |

| Cutting length | 20-400mm |

| Cutting speed | 10-200times/min |

| Production capacity | 3reams/min |

| Cutting precision | ±0.2mm |

| Power | 16Kw |

| Voltage | 380V/220V x 50HZ |

| Dimension(L*W*H) | 8800×2000×2000mm |

| Machine weight | 4500kg |

Production Flowchat

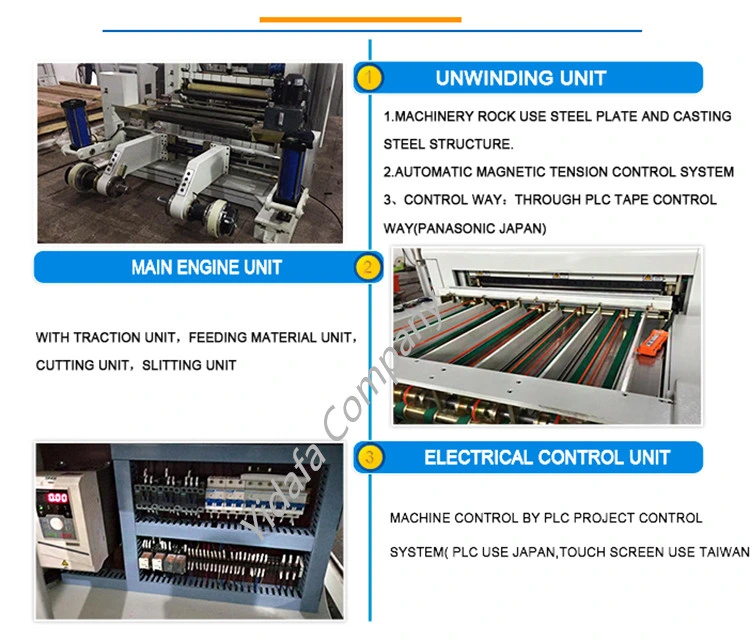

PRODUCRT FEATURE:1.Main engine frequency adjust speed,PLC touch screen control system,auto counter quantity, auto fixed length, auto machine stop when had alarm , auto tension control , color code track etc function.2.Feeding roll use auto loading system(150#cylinder), air shaft use 3#(74mm paper tube core)3.Machine rack use 10mm thick cast iron steel plate with steel structure. Bottom of cutting knife use heavy casting structure, Guide rollers using static balanced aluminum alloy guide roller.4.Traction drive fixed position use servo motor system, traction driver roller use steel structure. Feeding traction way is through motor move the chain wheel to drag the rubber roller. The receiving platform is normal automatic finished materials table, control by motor.5.Our Machine is best jumbo roll cross cutting machine, it have high precision. High speed and receiving sheet paper flat.

Workshop and Machine PackagingCompany Profile

Qingdao YiDaFa International Trade is located in Free Trade Zone, Qingdao, Shandong, China. The registered capital of our company is RMB 5 million. We have 6 production areas, 129 team members, including 39 technical experts, who have rich experience in the field of paper machine design. The main products of our company cover a variety of paper machinery, paper products processing machinery and related parts. We have done this business for more than 20 years in China. In 2014, we founded international trade department in order to stand in the international market. Our mission is to be the leader in paper machinery field. Our principle is Science, Quality and Green. As we know, environmental pollution and waste of resources are two prominent problems in the traditional paper industry. To advocate the concept of global environmental protection, each of our paper machines has the advantages of energy saving, high efficiency and reducing pollution. Especially in waste water recycling use, we have unique processing technology. Welcome any customers from all over the world to contact us freely. It is our sincere hope that we can establish a long-term and stable friendship with our strategic partners. Then we will work and explore together to create a brilliant future.

Our Advantages1.The business contact on both sides will reply within 16 hours .2.During warranty period, the company provide the relevant technical services for free,such as equipment quality problem resulting from the design and manufacturing equipment, which the company will be responsible for replacement and maintenance.3.After the expiration of the warranty, our company provide customers with a lifelong technical service and spare parts with preferential price and efficient manner over a long period of time.FAQ:

1.How to install and maintain the machine?

Firstly, we will provide the installation guidance with the machine for your reference.Secondly, our company is responsible for training production workers for you, ensuring that the workers will be independent operation.2.How can we get the matching accessories or wearing parts conveniently?During the warranty, Our company can replace the accessories for free .Out of warranty,we can provide them at the preferable price. In fact, the wearing parts are standard parts that you could get it in your country at your convenience.