Category

China Factory Wholesale Price New Automatic Cutting BOPP PE PVC Film Foil Paper Fabric Roll Cutter Slit Slitter Rewinder Slitting Rewinding Making Machine

Package size per unit product 200.00cm * 180.00cm * 200.00cm Gross weight per unit product 2000.000kg China Factory Whol

Basic Info

| Model NO. | HN1600 New Generation |

| After-sales Service | 7*24 Hours Online Support When Start Operation |

| Warranty | 2 Years Guarantee for The Key Parts |

| Application | Slitting |

| Type | Roll Slitter |

| Work Method | Flat Knife Slitting |

| Structure | Frame Part |

| Packaging | Case |

| Classification | Film Slitting |

| Applicable Process | Final Inspection |

| Suitable Substrates | Film Cutting |

| Packaging Material | Exporting Wooden Box |

| Speed | 500m/Min |

| Slitting Width | 1300mm |

| Tension Control | Automatic |

| Blade | Shavor Blade |

| Rewinding Shaft | Slipping Air Shaft |

| PLC | Mitsubish |

| Servo Motor | Taiwang |

| Mini Slitting Width | 30mm |

| Lead Time | 35 Days |

| Rewinding Dia | 600mm |

| Unwinding Dia | 800mm |

| Transport Package | Standard Exporting Wooden Box |

| Specification | 1300mm |

| Trademark | HAVESINO |

| Origin | China |

| HS Code | 8441100000 |

| Production Capacity | 20PC/Month |

Packaging & Delivery

Package size per unit product 200.00cm * 180.00cm * 200.00cm Gross weight per unit product 2000.000kgProduct Description

China Factory Wholesale Price New Automatic Cutting BOPP PE PVC Film Foil Paper Fabric Roll Cutter Slit Slitter Rewinder Slitting Rewinding Making Machine HN1600 SLITTING MACHINE Automatic Tenstion ControlAutomatic Unloading FunctionAutomatic Unloading Turret FrameFilm/Foil/Non-Woven/Label/Lamination Material Slitter RewinderHAVESINO Material to machine

Click one you are interested

APPLICATION A. 12-180um HOT STAMPING FOIL,COLDING FOIL,HOLOGRAPHIC FOILS,METALIZED FOIL and so on B. 12-180um PRIMARY FILM (BOPP,PVC,LDPE,PET,SINGLE SILICON FILM and so on) C. 12-180um LAMINATES (FILM to FILM,FILM TO FOIL,FILM TO PAPER and so on) D. Non-Woven FABRIC E. 40-80gram PAPER/LABEL/ADHESIVE LABEL F. 20-40UM ALUMINUM FOIL AND OTHER MATERIAL (PlS CHECK WITH THE SALES MANAGER)

BASIC INFORMATION

| 1 | SLITTING WIDTH | 300mm-1300MM |

| 2 | SLITTING THICKNESS | 12-250UM |

| 3 | UNWIND DIA. | MAX1000MM |

| 4 | UNWIND CORE I.D. | SHAFTLESS 3 INCH AND 6 INCH |

| 5 | REWINDING DIA. | MAX 600MM |

| 6 | REWINDING WIDTH | MINI 30MM |

| 7 | REWINDING CORE I.D | 3 INCH SLIPPING AIR SHAFT |

| 8 | SLITTING UNIT | RAZOR BLADE EACH 10 PCS |

| SHEAR CIRCLE BLADE 10 PCS | ||

| 9 | MECHANICAL SPEED | MAX550M/MIN |

| 10 | WORKING SPEED | MAX500M/MIN |

| 11 | MACHINE FRAME THICKNESS: | 50MM |

| 12 | METER COUNTER: | METER COUNTER |

| 13 | WASTE EDGE UNIT: | AIR BLOWER |

| 14 | POWER SOURCE | 380V,3 PHASE 4 WIRES,50Hz |

| 15 | PNEUMATIC SOURCE | 0.8MPA |

| 16 | LASER POSITIONING | 10 PCS |

| 17 | WITH AUTO UNLOADING FUNCTION FOR FINISHED ROLL | |

| 18 | MACHINE SIZE (REF. ONLY): | 2950mm(not including unloading frame tree)×2550mm×1970mm |

| 19 | 4590mm(including the unloading frame tree)×2550mm×1970mm | |

| 20 | FLOOR SPACE(REF.ONLY): | 4200MM*3300MM |

| 21 | N.W/G.W (REF. ONLY): | 3000/3500 |

FUNCTIONAL DESCRIPITION Rewinding: 1 3 INCH SLIPPING FRICTION AIR SHAFT to ensure the rewinding tension stable; 2 Full width pressing rollers by air control to ensure the finished roll surface keep smooth;3 Anti Stati Remove Brush for both up and down rewinding press roller 4 Small indiviual press roller specially designed for the individual roll which not average thickness 5 Manual laser core position units help to set paper/plastic cores easily and quickly, begin next slit run with very short downtime.6 Automatic tension control to ensure the rewinding tension stable. Unwinding: 1 Magnetic Brake with load cell close loop system for unwind tension control; 2 3 inch and 6 inch shaftless uwinding system, easily change the jumbo roll;3 Hydraulic lifting system to help the operator loading the jumbo roll max. 1 ton from floor; 4 Material splice table, easy change and guarantee edge consistency ;5 EPC ultrasonic edge guider to avoid the influnce from shinning materia which reflect light back;6 Back Control Button & Screen Display make the operator easily control the slitter at back side;3 SECURITY GRAVITY CARPET to ensure the safty of the operator; =Blade Unit: 1 Shavor or Razor blade setting easily setting by wrench losing and fixing, very quick and easy;2 Shear Circle Blade slit for all kind of material stable slitting at high speed. Unloading: 1 AUTO VERTICAL ROLL UNLOADING DEVICE not only can move horizontally and parallelly,make finished roll unloading much easier than before; 2 Auto unloading function to avoid manual hand push, save time and energy of operator.

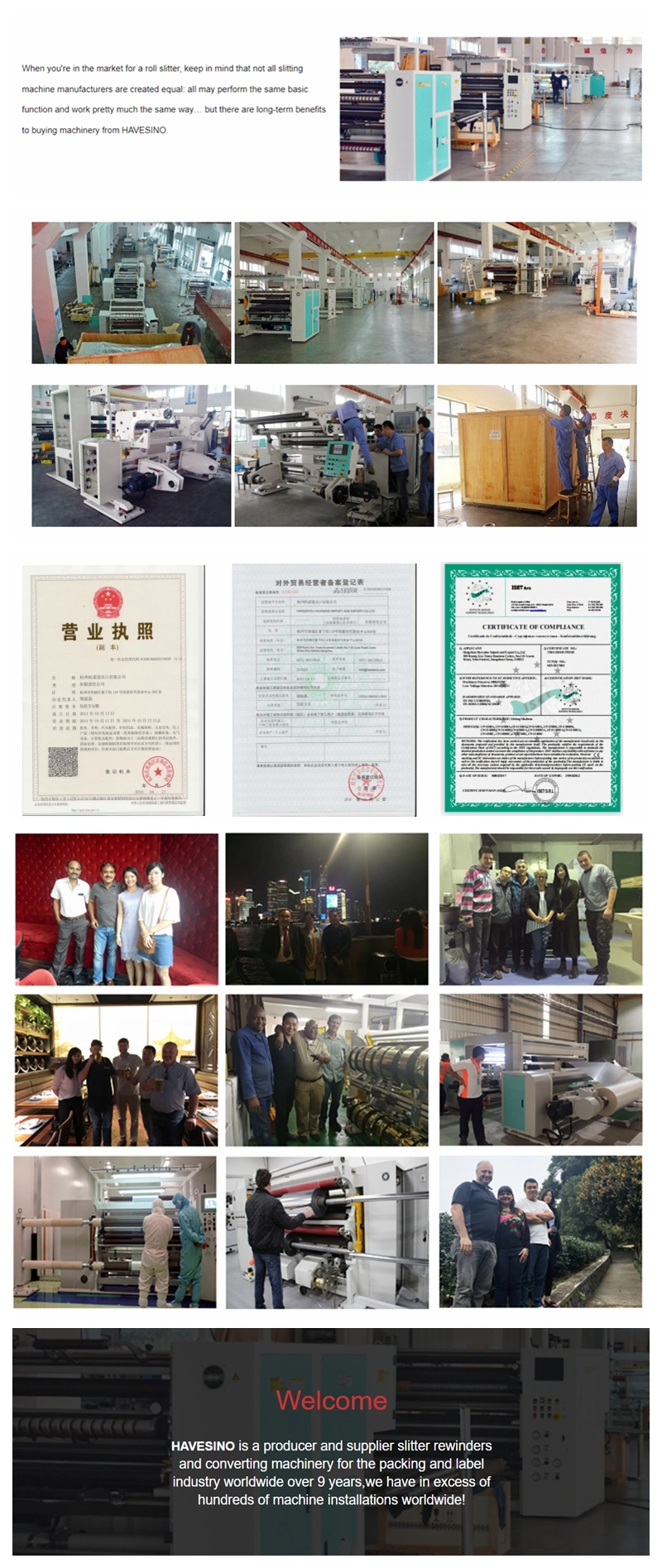

About HavesinoHAVESINO is one of top suppliers for Semi Automatic and Fully Automatic thermal paper slitter re-winders and converting machinery for more than 12 years. We have in excess of hundreds of machine installations all around the world!HAVESINO is one of the leaders in design, developing and building of quality,high performance of thermal paper slitter re-winders and the support machine such as core loader, core-less machine and fully automatic packing lines.

GUARANTEE AND SERVICE

1 100% Test and Check Before Shipment. 2 Detailed Instruction Manual. 3 Two Year Guarantee for All Key Parts. 4 7×24Hours Online Service5 Installing and Operator Training Service Provided. 6 Whole-Life Free Technical Support. 7 Regular On-Site Routine Inspection.